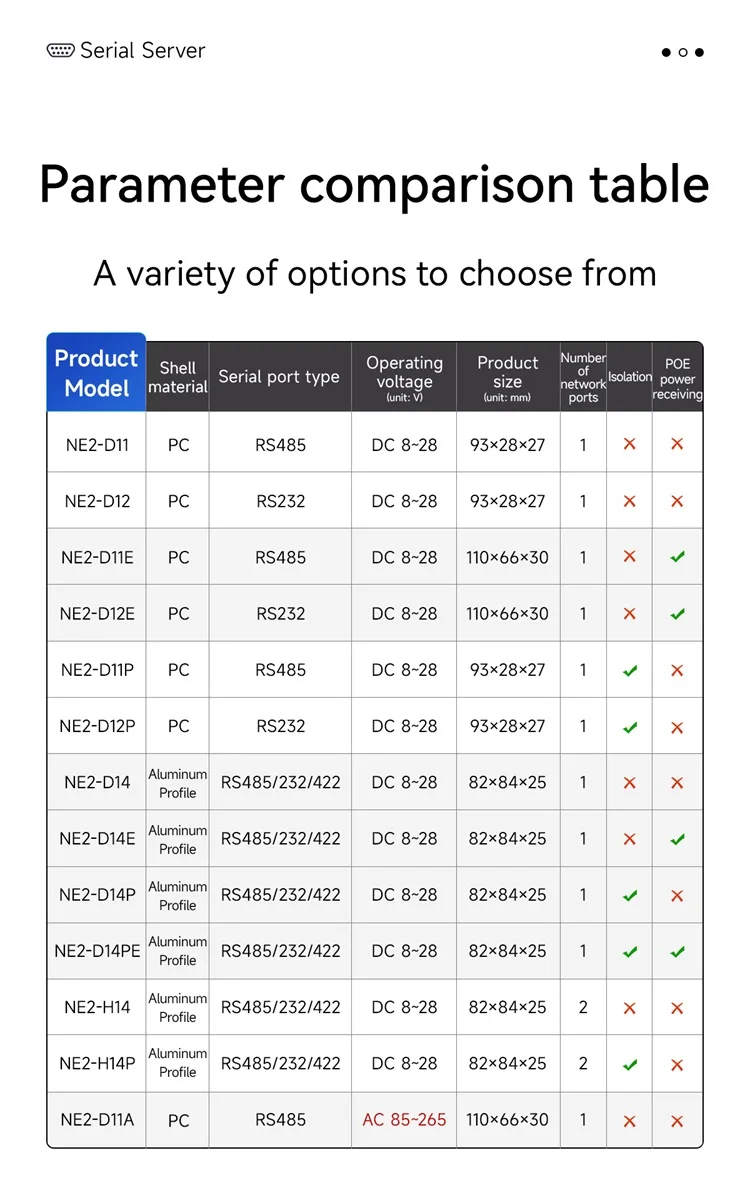

NE2-D11E & NE2-D12E Industrial Serial Servers

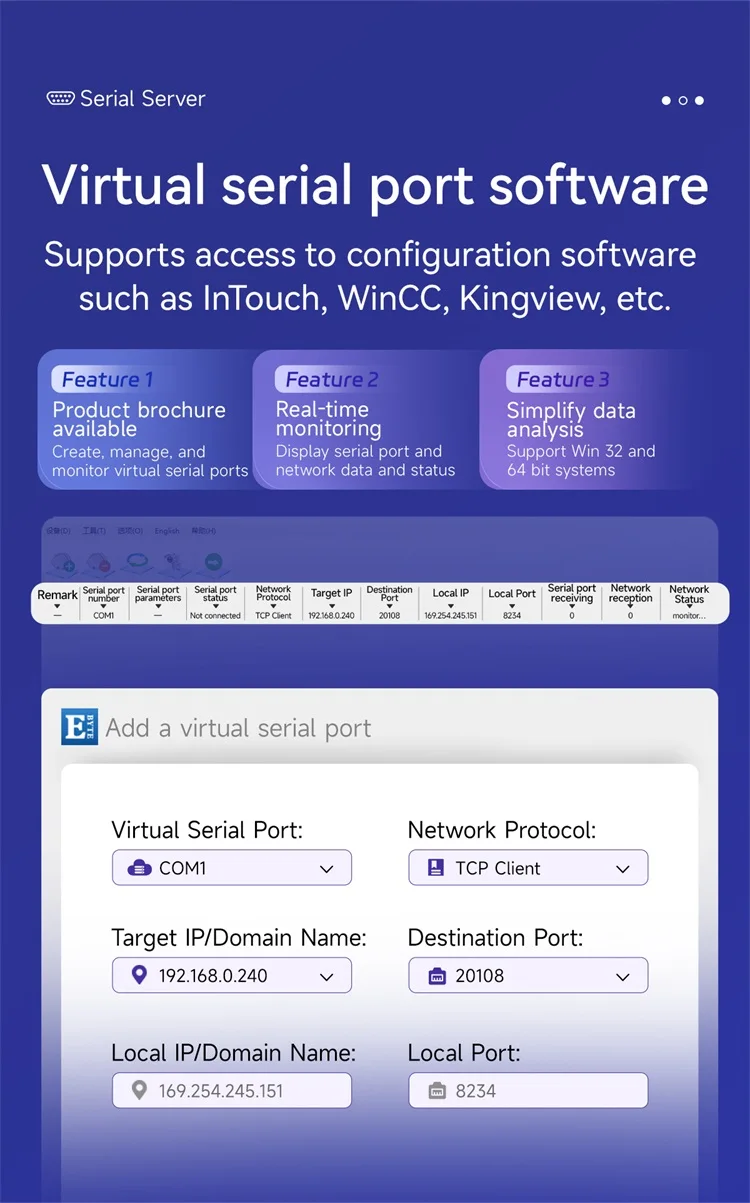

NE2-D11E (RS485) and NE2-D12E (RS232) are industrial-grade serial-to-ethernet servers enabling bidirectional transparent data transmission between serial devices and TCP/IP networks with MQTT/HTTP cloud connectivity.

Core Product Features

Robust Industrial Design

PC-encased metal housing withstands -40°C to 85°C operating temperatures with DIN rail mounting options for harsh environments.

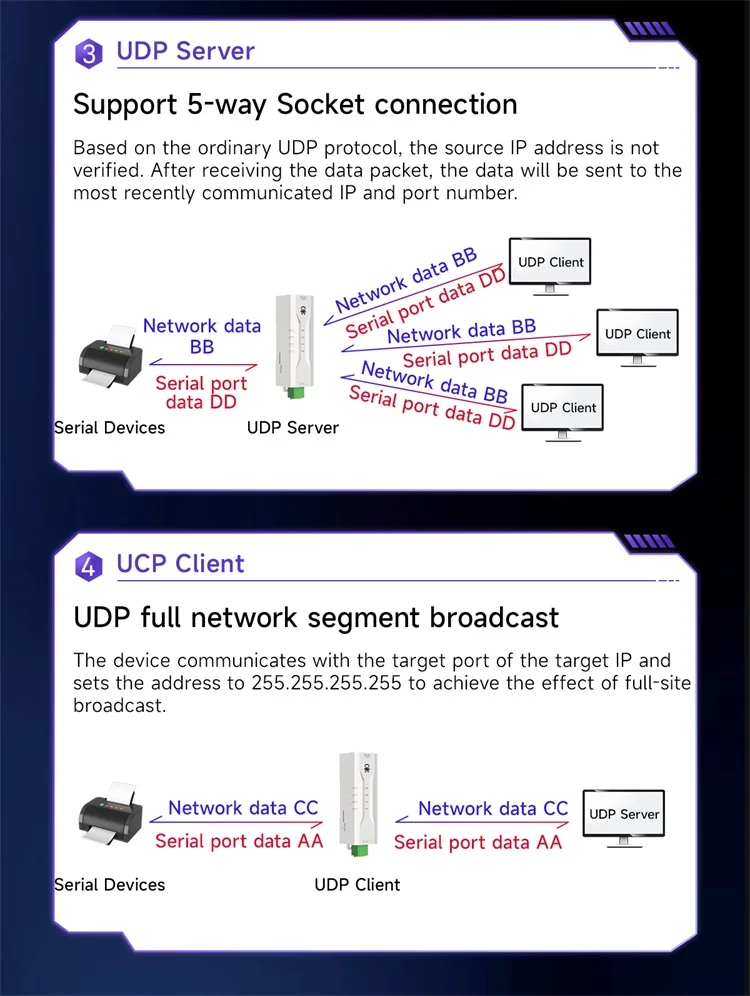

Multi-Protocol Gateway

Supports Modbus TCP↔RTU conversion with 5 gateway modes including storage-type and multi-master configurations.

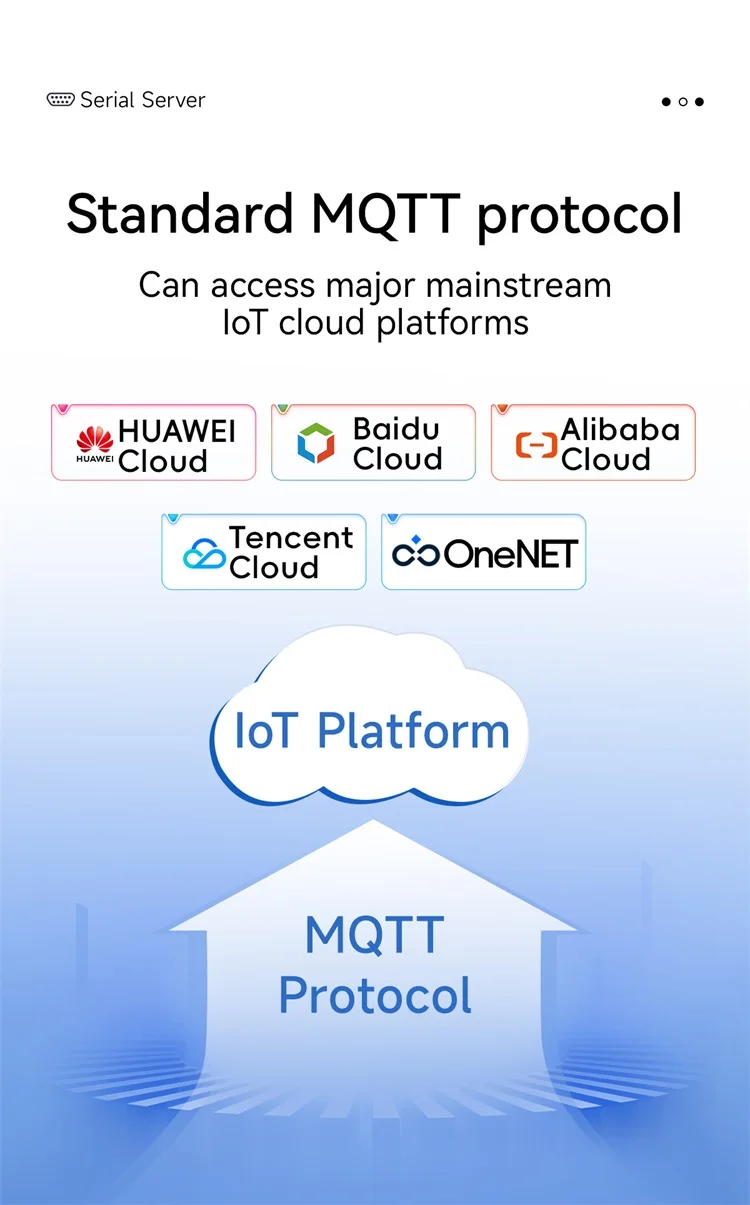

Cloud Integration

Direct connectivity to AWS IoT Core, Azure IoT Hub, and major Chinese clouds (Aliyun/Baidu/OneNET) via MQTT 3.1.1.

Network Resilience

Automatic reconnection + timeout reboot (configurable 1-60min) with heartbeat/registration packets for 24/7 operation.

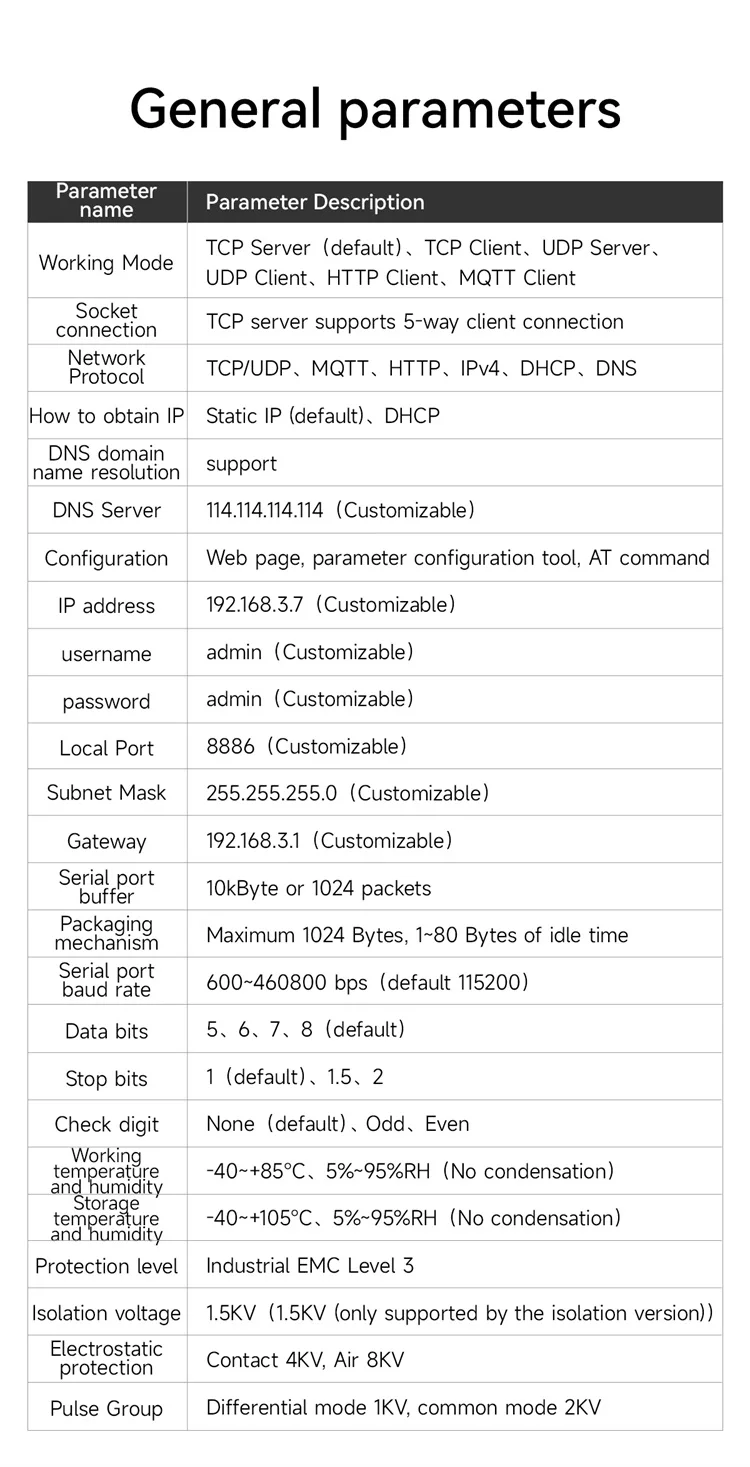

Technical Specifications

Physical Parameters

- Dimensions: 110×66×30mm (W×H×D)

- Weight: 185g ±5%

- Housing: PC material with IP30 protection

Electrical Specifications

- Power Input: DC 8-28V via 2P 5.08mm terminal

- Power Consumption: 1.2W typical @ 12VDC

- Isolation: 1.5kV DC isolation (signal/power)

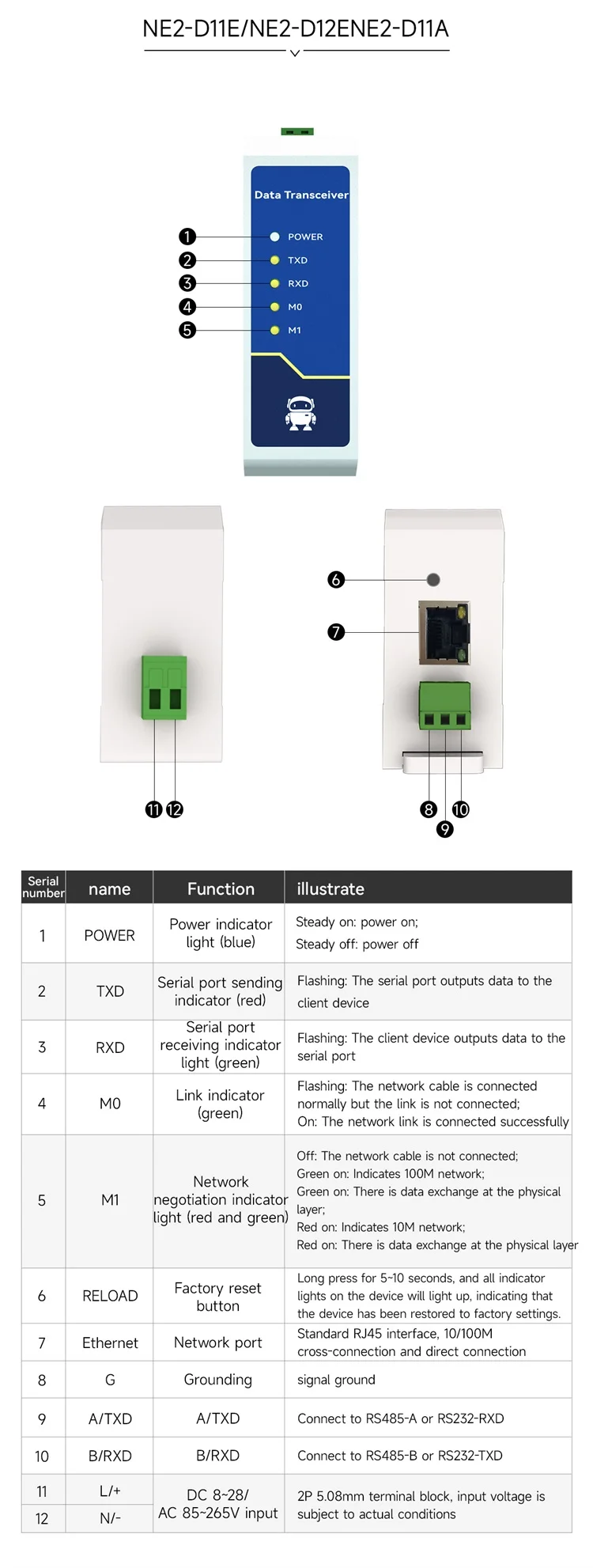

Communication Interfaces

- Ethernet: 10/100M RJ45 auto-MDIX

-

Serial Protocols:

- NE2-D11E: RS485 (3P 3.81mm terminal)

- NE2-D12E: RS232 (DB9 female)

- Baud Rate: 600 bps - 460.8 kbps (default 115.2kbps)

Performance Metrics

- Packet Handling: 10KB serial buffer with frame header distribution

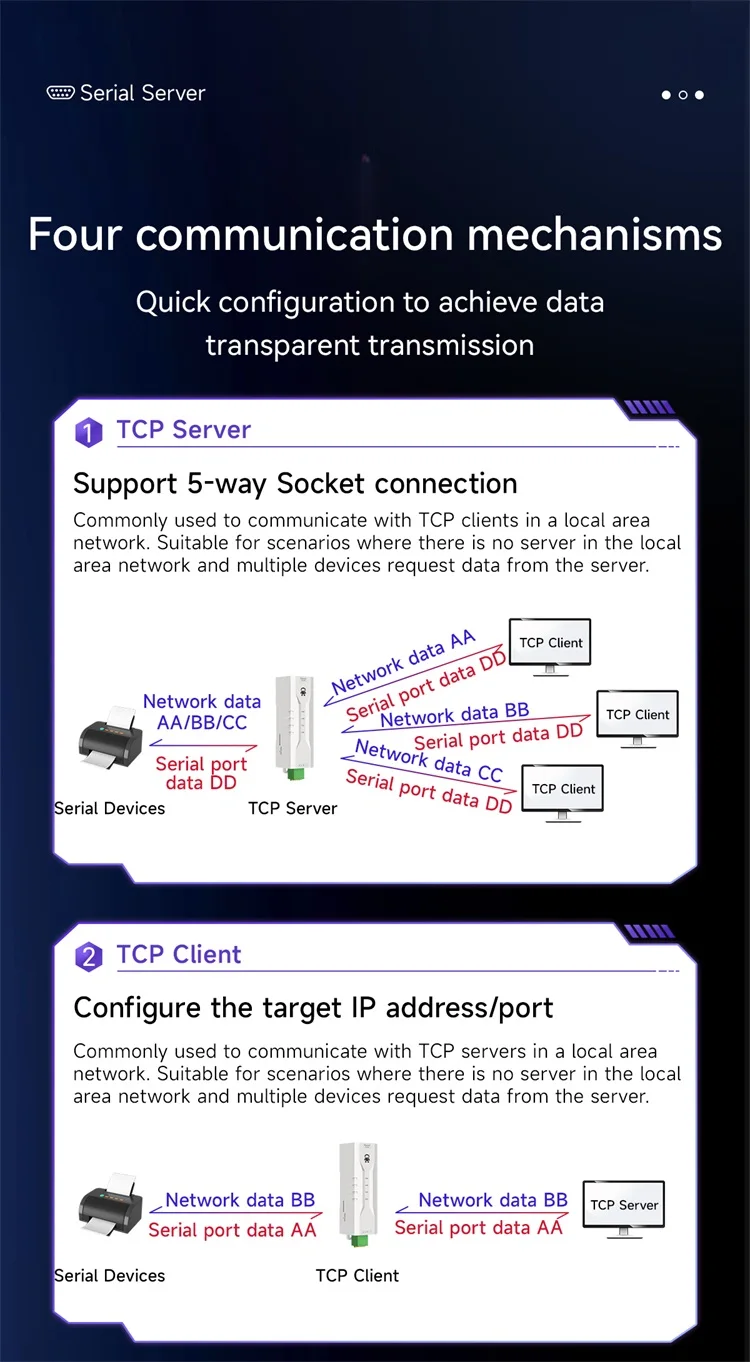

- Socket Capacity: Dual sockets (5 clients/server socket)

- Latency: <5ms serial-to-ethernet conversion

Industrial Application Scenarios

Factory Automation

Connect legacy PLCs (Siemens S7-200/Modicon) to SCADA systems via Modbus TCP without hardware replacement.

Energy Monitoring

Transmit smart meter data (RS485) to cloud platforms like AWS IoT for real-time consumption analytics.

Building Management

Integrate HVAC controllers (RS232) into BACnet/IP networks through HTTP POST/GET API endpoints.

Remote Site Monitoring

Deploy in substations with DHCP/DNS support for automatic network configuration in unmanned locations.

Predictive Maintenance

Enable vibration sensors to push data via MQTT to Azure IoT Hub for AI-driven failure prediction.